By Shereen Shabnam

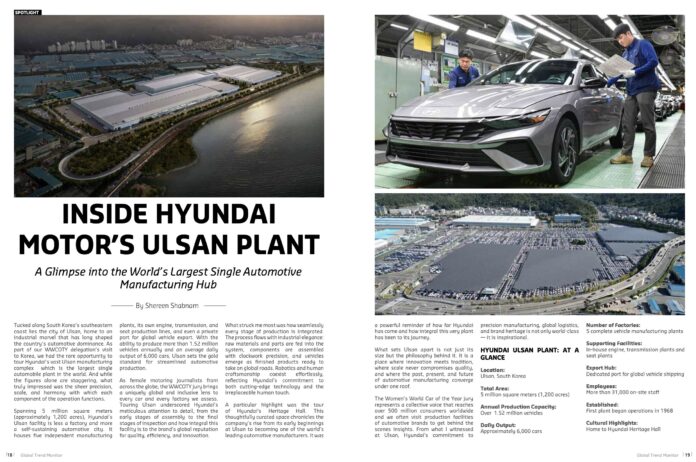

Tucked along South Korea’s southeastern coast lies the city of Ulsan, home to an industrial marvel that has long shaped the country’s automotive dominance. As part of our WWCOTY delegation’s visit to Korea, we had the rare opportunity to tour Hyundai’s vast Ulsan manufacturing complex which is the largest single automobile plant in the world. And while the figures alone are staggering, what truly impressed was the sheer precision, scale, and harmony with which each component of the operation functions.

Spanning 5 million square meters (approximately 1,200 acres), Hyundai’s Ulsan facility is less a factory and more a self-sustaining automotive city. It houses five independent manufacturing plants, its own engine, transmission, and seat production lines, and even a private port for global vehicle export. With the ability to produce more than 1.52 million vehicles annually and an average daily output of 6,000 cars, Ulsan sets the gold standard for streamlined automotive production.

As female motoring journalists from across the globe, the WWCOTY jury brings a uniquely global and inclusive lens to every car and every factory we assess. Touring Ulsan underscored Hyundai’s meticulous attention to detail, from the early stages of assembly to the final stages of inspection and how integral this facility is to the brand’s global reputation for quality, efficiency, and innovation.

What struck me most was how seamlessly every stage of production is integrated. The process flows with industrial elegance: raw materials and parts are fed into the system, components are assembled with clockwork precision, and vehicles emerge as finished products ready to take on global roads. Robotics and human craftsmanship coexist effortlessly, reflecting Hyundai’s commitment to both cutting-edge technology and the irreplaceable human touch.

A particular highlight was the tour of Hyundai’s Heritage Hall. This thoughtfully curated space chronicles the company’s rise from its early beginnings at Ulsan to becoming one of the world’s leading automotive manufacturers. It was a powerful reminder of how far Hyundai has come and how integral this very plant has been to its journey.

What sets Ulsan apart is not just its size but the philosophy behind it. It is a place where innovation meets tradition, where scale never compromises quality, and where the past, present, and future of automotive manufacturing converge under one roof.

The Women’s World Car of the Year jury represents a collective voice that reaches over 500 million consumers worldwide and we often visit production facilities of automotive brands to get behind the scenes insights. From what I witnessed at Ulsan, Hyundai’s commitment to precision manufacturing, global logistics, and brand heritage is not only world-class — it is inspirational.

Hyundai Ulsan Plant: At a Glance

- Location: Ulsan, South Korea

- Total Area: 5 million square meters (1,200 acres)

- Annual Production Capacity: Over 1.52 million vehicles

- Daily Output: Approximately 6,000 cars

- Number of Factories: 5 complete vehicle manufacturing plants

- Supporting Facilities: In-house engine, transmission plants and seat plants

- Export Hub: Dedicated port for global vehicle shipping

- Employees: More than 31,000 on-site staff

- Established: First plant began operations in 1968

- Cultural Highlights: Home to Hyundai Heritage Hall